The Operational Intelligence Paradox: Why Leaders Who Fix Processes First Win the Technology Game

How Smart Executives Transform Hidden Inefficiencies into Competitive Advantages

The $2.3 Million Question Nobody's Asking

Last month, I delivered brutal news to a CEO whose company was "crushing it"—23% revenue growth, expanding market share, investor confidence through the roof. Their technology was silently bleeding $340,000 annually in hidden inefficiencies. Three weeks later, I sat across from another executive. Different industry, larger scale. Same problem: $1.3 million walking out the door through fractured processes and technology debt.Both asked the same question: "How did we not see this?"Here's what I've learned after auditing 200+ companies: The organizations that scale efficiently aren't the ones spending the most on technology—they're the ones who understand their operational reality before they optimize it.

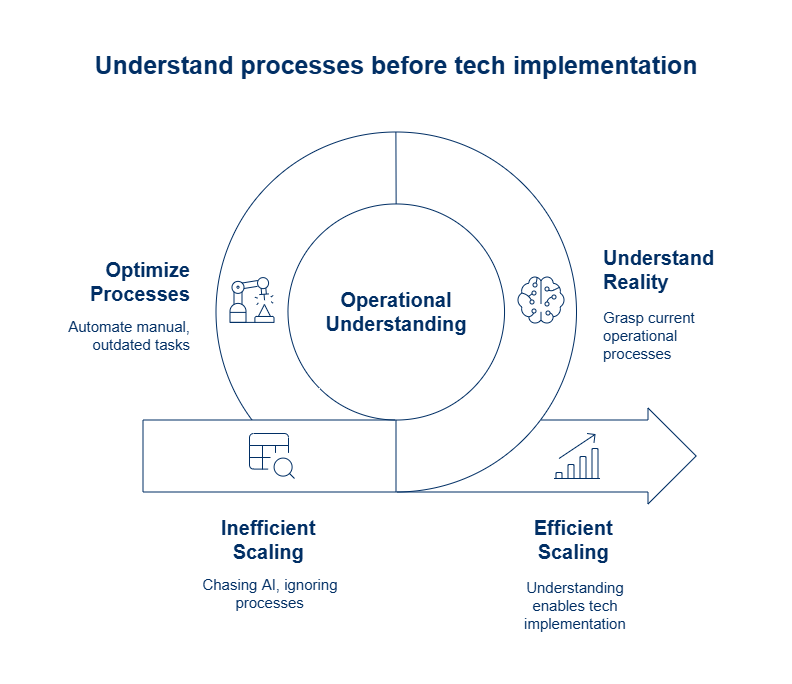

This is the Operational Intelligence Paradox: You can't successfully implement tomorrow's technology if you don't understand today's processes

Most leaders chase AI promises while their ERP talks to their CRM through Excel macros. They invest millions in predictive analytics while burning hundreds of thousands on manual processes that should have been automated years ago.

The Hidden Cost Architecture That's Crushing Your Margins

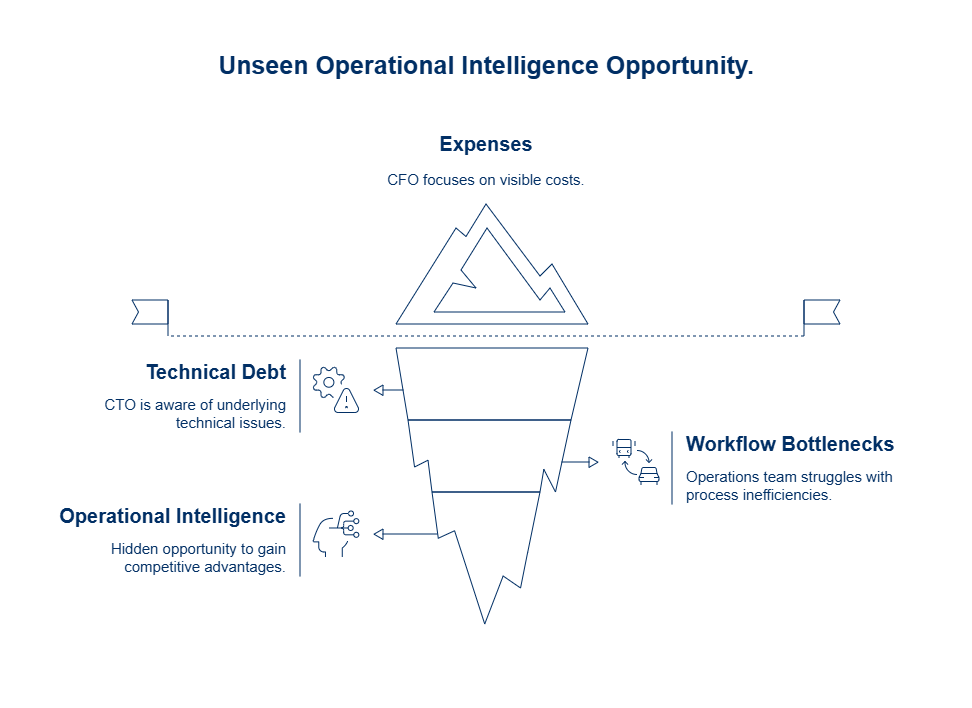

Here's what every technology audit reveals: Your P&L shows "software expenses," "security tools," and "workflow inefficiencies"—but nobody connects these scattered line items to the $2.3 million hemorrhaging from operational friction.

The math across our client base is consistently brutal:

Small companies (100-500 employees):

- $180K-$450K annual waste on redundant tools and manual processes

- 42% of AI initiatives abandoned due to process foundation failures

- Average of 23 disconnected software tools requiring manual integration

Larger clients (500+ employees):

- $800K-$2.5M in hidden technology costs

- $380K annual productivity loss from security gaps alone

- 70% of digital transformation failures rooted in process, not technology issues

The visibility gap: Your CFO sees expenses. Your CTO sees technical debt. Your operations team sees workflow bottlenecks. Nobody sees the operational intelligence opportunity that could transform these costs into competitive advantages.

What Operational Intelligence Actually Means (And Why It Changes Everything)

After two decades leading digital transformations, I've seen this pattern repeatedly: Organizations that thrive treat their operational data as strategic intelligence. They understand their processes so deeply they can optimize them with surgical precision.

Operational Intelligence combines Process Intelligence with strategic technology visibility to answer three critical questions:

- What's actually happening in our operations right now? (Process Intelligence)

- Where is technology friction costing us money? (Technology Visibility)

- How do we eliminate waste while scaling efficiently? (Strategic Integration)

Real-world example: A 150-person manufacturing client discovered their "efficient" order processing actually required manual data entry across four systems, taking 3 days per order. Process Intelligence revealed the workflow reality. Technology visibility showed the true cost: $340K annually in labor inefficiency and customer friction.

The fix: Unified platform with automated workflows. The result: 4-hour order processing, $847K annual savings, 25% higher valuation than comparable companies.

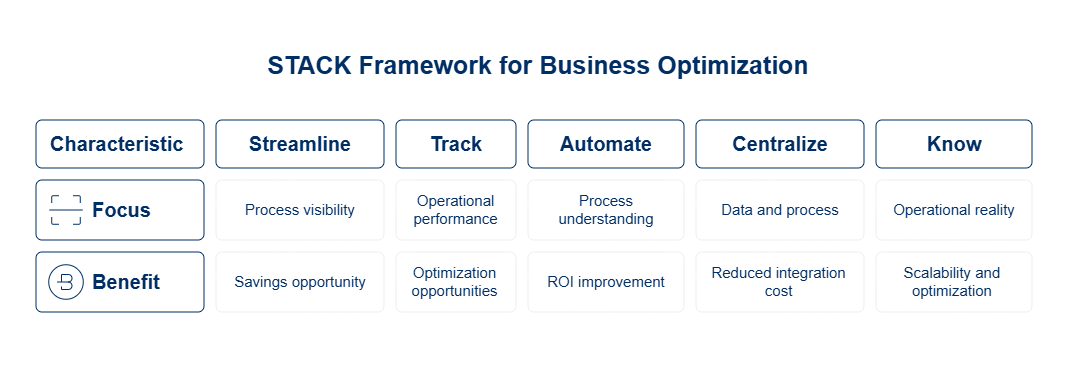

The S.T.A.C.K. Framework for Operational Intelligence

When I work with leadership teams, I use our integrated S.T.A.C.K. methodology to transform hidden inefficiencies into measurable competitive advantages:

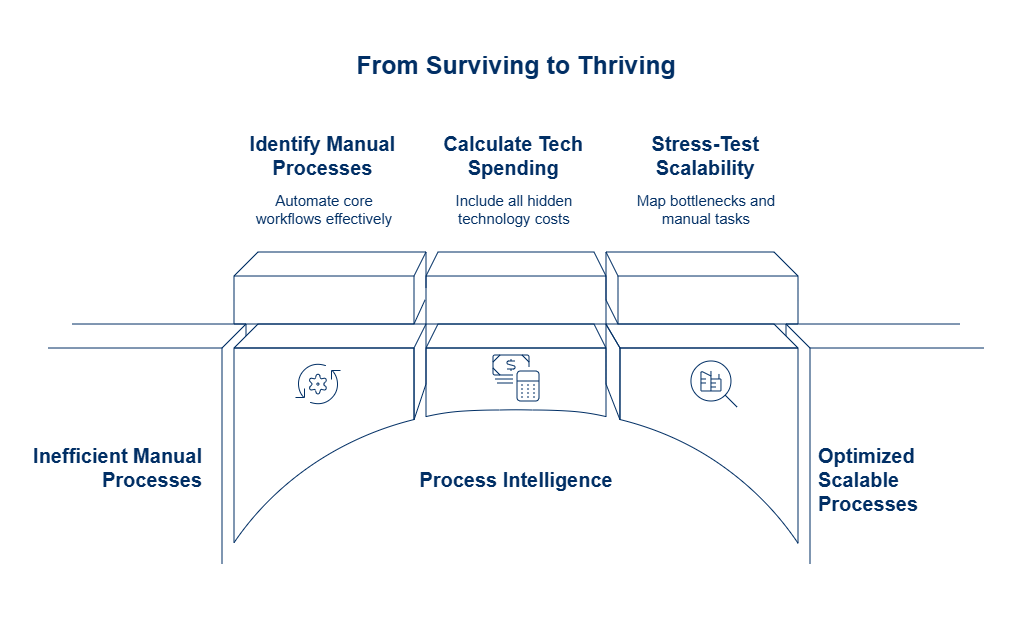

The Three Questions That Separate Survivors from Thrivers

- What manual processes are we doing that our competitors have automated? - Walk through your core workflows with Process Intelligence. If your team copies data between systems, sends status emails manually, or creates reports by hand, you're not just inefficient—you're falling behind competitively.

- How much are we really spending on technology per employee? - Include everything: software licenses, cloud services, internal IT support, training time, productivity lost to system downtime, and manual workarounds. Most companies discover this number is 40-60% higher than budgeted—and 200-300% less effective than optimized.

- If we doubled revenue tomorrow, would our processes scale or break? - Stress-test your operational reality, not your theoretical capabilities. Map the bottlenecks. Identify manual processes that would become impossible at scale. Process Intelligence reveals the truth your org chart won't tell you.

Why Process Intelligence Must Come Before AI Investment

Here's the uncomfortable truth about AI failure rates: 42% of companies abandoned AI initiatives in 2024—up from 17% in 2023. The primary reason isn't technology limitation—it's process foundation failure.

Traditional AI approach: Invest $1 million in predictive models, hope for insights, discover your data reflects broken processes.

Operational Intelligence approach: Invest $70K-$310K in understanding your current operations, optimize based on real data, then strategically apply AI where it delivers measurable value.

The results speak for themselves:

Process Intelligence delivers 200-500% ROI within 2-3 years

- 4-12 month payback periods

- Immediately visible, measurable improvements

- Foundation for successful AI implementation

Strategic advantage: Organizations that master their processes first build operational excellence that enables rather than assumes successful technology adoption.

The Competitive Advantage Window Is Closing

The Process Intelligence market projects 40-44% annual growth, reaching $42.7 billion by 2030. More importantly, the companies implementing Operational Intelligence now are pulling away from competitors who are still guessing at their operational reality.Three trends creating immediate opportunity:

- AI-Enhanced Process Optimization: Platforms evolving to prescriptive recommendations based on operational reality

- Hyper automation Convergence: Process Intelligence plus strategic automation delivering 40% increased business value

- Industry-Specific Operational Frameworks: Pre-built solutions accelerating time-to-value for focused verticals

The Choice: Guess or Know

Your technology infrastructure is either a profit center or a cost center. There's no neutral position. Every day you delay operational optimization, you're choosing to bleed money while competitors build sustainable advantages. The companies commanding premium valuations aren't the ones with the most sophisticated AI—they're the ones with technology that makes their operations measurably more effective.

The fundamental question: Do you want to guess at your operational efficiency or know it with surgical precision?

Organizations face a fundamental decision: continue bleeding money through operational inefficiencies while competitors build systematic advantages, or transform hidden costs into competitive weaponry through disciplined operational intelligence. The companies dominating their markets understand their processes deeply enough to optimize them strategically. They implement technology that amplifies rather than complicates their competitive positioning.

How I Work with Clients: Transforming Hidden Costs into Strategic Assets

After working with 200+ organizations across manufacturing, healthcare, and professional services, I've learned that successful operational transformation follows a disciplined, phased approach. Here's how I guide leadership teams through building sustainable competitive advantages.

Our process includes:

- Process Intelligence audits across your highest-impact workflows

- Technology visibility analysis that tracks real usage versus licensed capacity

- Baseline metric establishment connecting process efficiency to financial performance

- Strategic roadmap development prioritizing immediate wins alongside long-term positioning

Typical discovery: Most organizations discover 40% of their operational complexity is self-inflicted—and immediately actionable.

Our role is providing the strategic bridge between where you are and where the market demands you to be.

- Process Understanding Before Technology Implementation: I start with understanding your actual workflows, not implementing trendy solutions. Process Intelligence reveals operational reality versus organizational assumptions.

- Strategic Integration Over Point Solutions: My methodology connects process optimization with technology visibility, eliminating gaps that create hidden costs and operational friction.

- Capability Building Over Dependency Creation: I build internal champions and continuous improvement cultures, ensuring sustainability beyond our engagement.

- Measurable Outcomes Over Theoretical Projections: Every phase delivers transparent, immediately visible improvements with clear connection to strategic business objectives.

Lets Have a conversation to help you get better visibility to this specific questions -

What's one manual process your team could optimize this month using real operational data instead of assumptions?

Your competitive advantage depends on the answer—and how quickly you act on it.